ELECTRICAL TESTING SPOTLIGHT:

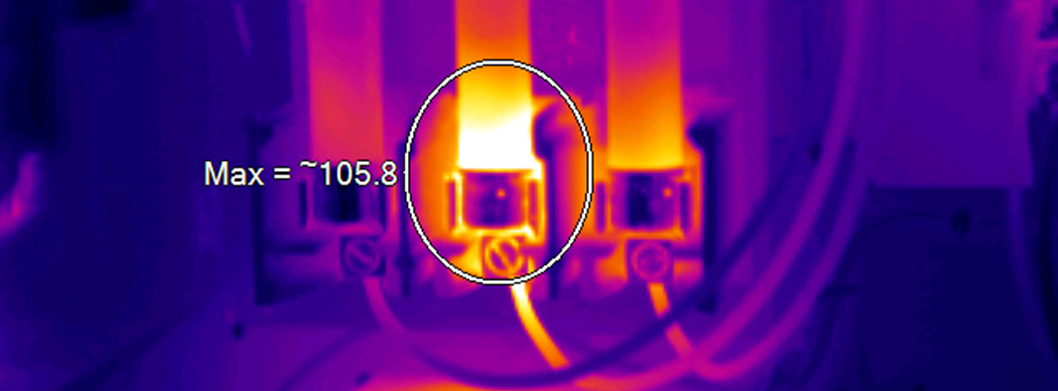

Infrared Thermography

Increased resistance in electrical components can be the result of equipment fatigue, faulty installation, exposure to the elements, and normal wear and tear. This increased resistance also results in increased heat, which is a primary cause for most electrical component failures.

LHEI experts are certified in the use of infrared thermography, an invaluable tool that identifies problems before they become disasters. Using a special infrared camera, ‘hot spots’ are visible that cannot be seen with the naked eye. This gives you the advantage of correcting the problem in early stages, saving time and cost.

PREVENTIVE MAINTENANCE TESTING AND CLEANING

Benefits:

- Minimize production losses due to unscheduled downtime

- Reduce energy consumption and costs associated with unplanned outages

- Quickly identify problems with non-intrusive infrared thermography, even when equipment is in operation

- Enhance worker safety and reduce the risk of serious injury

- Evaluate equipment installations during the commissioning of new facilities

- Validate post maintenance repair work and system conditions prior to warranty expiration

- Increase equipment reliability through the early detection of abnormal thermal conditions

Services:

LHEI conducts visual Inspections, mechanical verification checks, electrical testing and repair of low, medium, and high voltage electrical apparatus. Services include:- Electrical Power Studies

- Arc Flash Analysis

- Hi Pot Testing

- Short Circuit Analysis

After testing, we also perform repairs, upgrades, modifications, and life extension services for your vintage but serviceable switchgear.

Not sure which equipment needs maintenance or how often? Let us help you develop a maintenance program for your facility that can fit your budget.

ACCEPTANCE TESTING

Benefits:

- Ensure newly installed electrical equipment meets all specified requirements for safe installation and operation

- Identify installation problems before they effect both new and existing equipment

- Optimize power system performance

- Use electrical acceptance test results as baseline for future maintenance

Services Include:

- Acceptance testing on your new facility

- Test, maintain, repair and upgrade existing service of aging equipment

- Perform OSHA/NFPA required studies such as Arc Flash Hazard Analysis, Load Monitoring for future expansion, and other power system studies

What We Test:

- Switchgear and Switchboard Assemblies

- Cables, Low and Medium Voltage

- Circuit Breakers, Low, Medium, and High Voltage

- Protective Relays, EM, SS, and MB

- Metering Devices

- Regulating Apparatus

- Grounding Systems

- Motor Control Centers

- Battery Systems

- Emergency Systems

- Need something else? Ask us!

ACCEPTANCE TESTING

Benefits:

- Ensure newly installed electrical equipment meets all specified requirements for safe installation and operation

- Identify installation problems before they effect both new and existing equipment

- Optimize power system performance

- Use electrical acceptance test results as baseline for future maintenance

Services Include:

- Acceptance testing on your new facility

- Test, maintain, repair and upgrade existing service of aging equipment

- Perform OSHA/NFPA required studies such as Arc Flash Hazard Analysis, Load Monitoring for future expansion, and other power system studies

What We Test:

- Switchgear and Switchboard Assemblies

- Cables, Low and Medium Voltage

- Circuit Breakers, Low, Medium, and High Voltage

- Protective Relays, EM, SS, and MB

- Metering Devices

- Regulating Apparatus

- Grounding Systems

- Motor Control Centers

- Battery Systems

- Emergency Systems

- Need something else? Ask us!

POWER STUDIES

Know how well your electrical system supports the reliable operation of its loads. LHEI offers a range of power quality test tools for troubleshooting, preventive maintenance and long-term documenting and analysis. We can record and analyze data for power disturbances, equipment start-up, power quality, and more.

Benefits:

Minimize power disturbances before they cause failure

Services Include:

- Arc Flash Hazard Analysis

- Coordination & Short Circuit Studies

- Power Quality and Load Studies

- Energy Audits

- Harmonic Analysis

- Load Flow Analysis

- Power System Evaluation

- Project Feasibility Studies

- Single-Line Drawings

- Technical Training Seminars

- Transient Stability Studies

After the study, you will get a report documenting findings and recommendations specific to your electrical system.